Automation of industrial equipment

FROM TECHNICAL DESIGN, THROUGH DOCUMENTATION, TECHNOLOGY DELIVERY, IMPLEMENTATION, TEST PRODUCTION TO FOLLOW-UP SERVICE AND TECHNICAL SUPPORT.

Many years of experience and knowledge, dealing with projects and deliveries of technological units for the food and machinery industry.

Automatization of production and non-production processes

We solve partial units as well as complex solutions of entire lines

Automatization

By supplying automated control systems, we solve partial units and complex solutions for entire lines.

We deal with measurement and regulation. We put technological units into operation.

Software development according to customer requirements. SW modifications of existing equipment. Replacement of control systems.

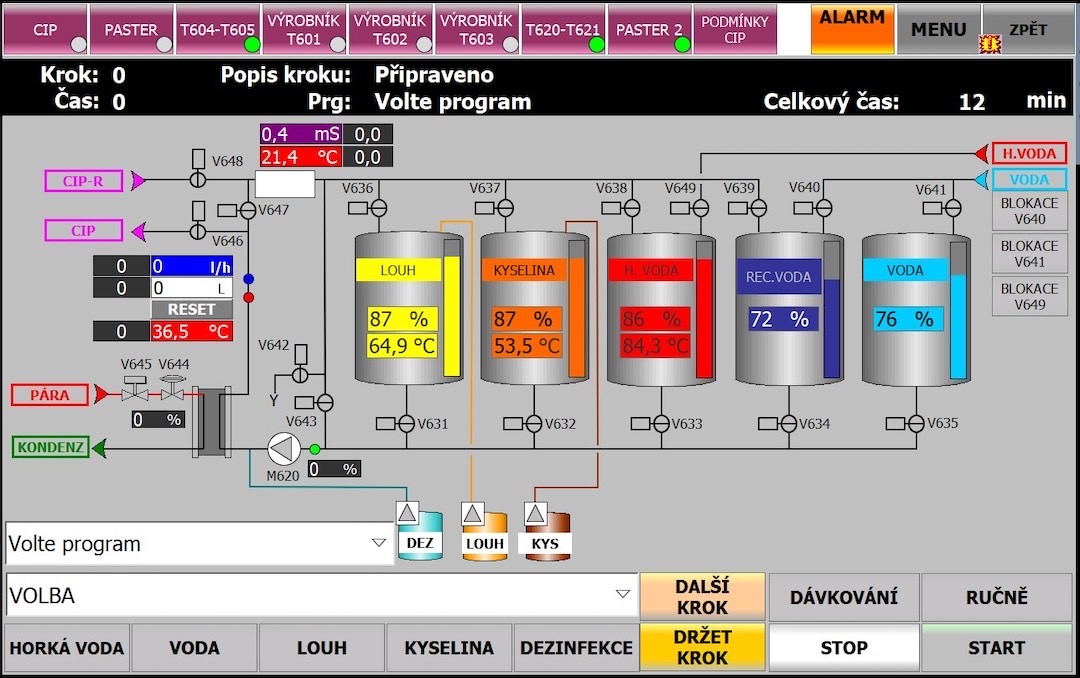

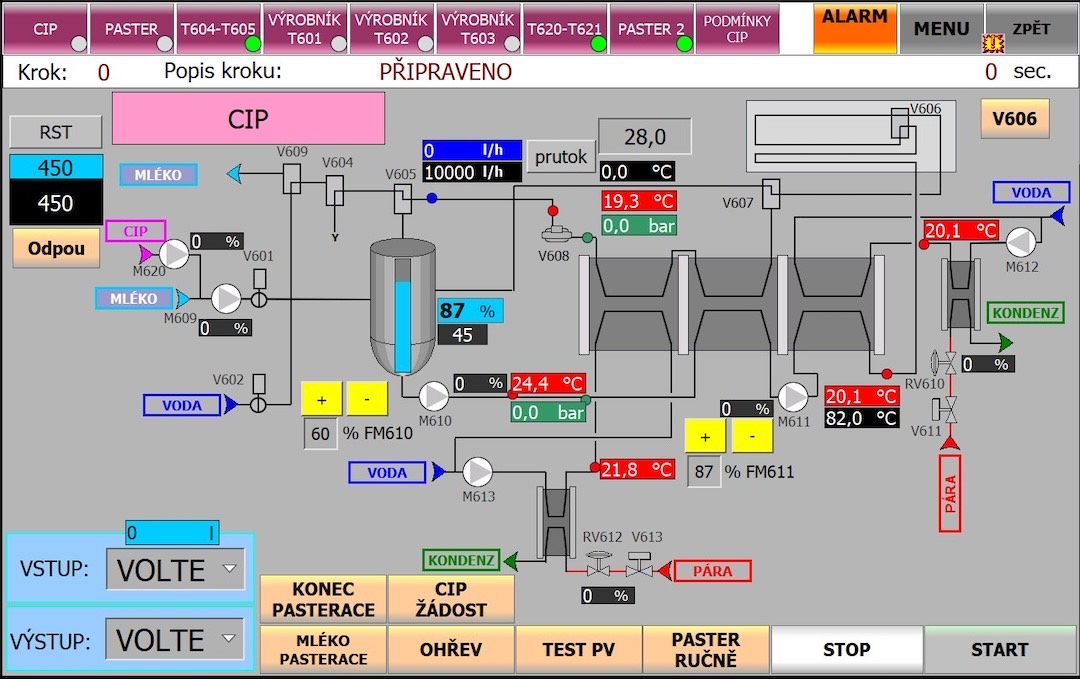

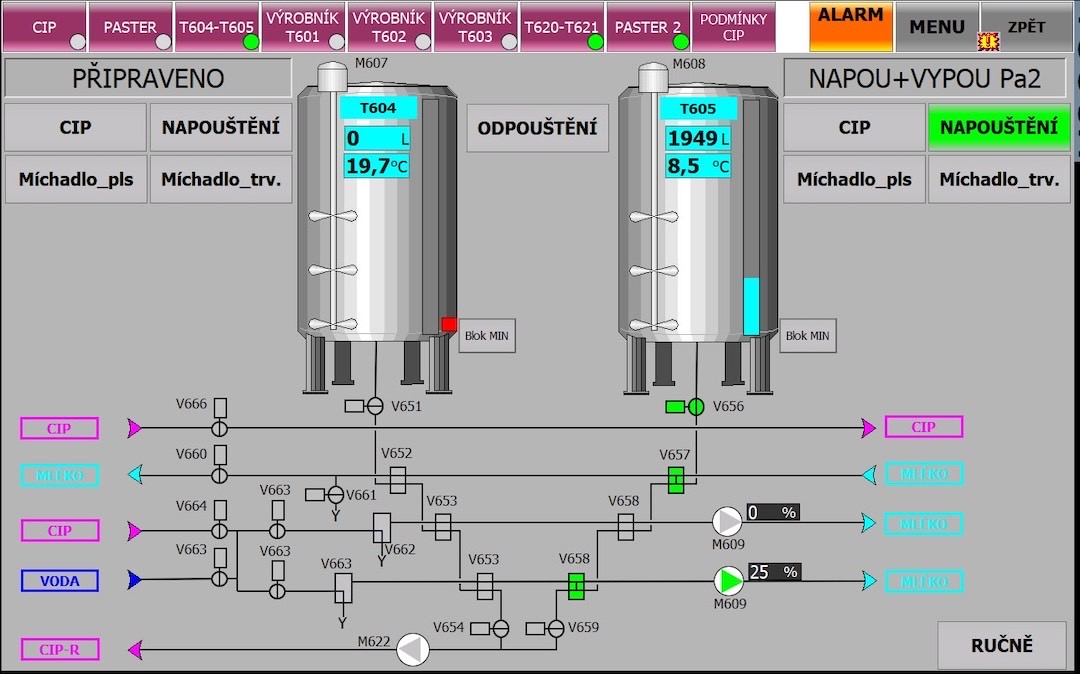

Visualization - monitoring

Design and realization of industrial networks – SCADA systems, HMI visualization – touch operator panels and PC.

Collection and archiving of production data, recording and statistics of machine failures in the line and following evaluation.

Analysis of process monitoring, VPN access through internet IP cameras.

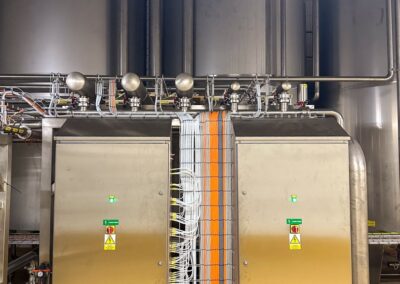

Supply of technology

We provide you with the entire technology – tanks, heat exchangers, centrifuges, pumps, valves and fittings.

Alfa Laval is our main technology distribution partner.

We will create a system that fully meets your individual needs and requirements.

Technologies for the food and machinery industry

From the technical design phase to technical support

APZ control systems s.r.o. is a company with 22 years of experience, dealing with projects and deliveries of technological systems for the food and machinery industry.

It offers a wide range of services in the field of measuring and control technology, automatic control of production and non-production processes, their visualization and archiving with further evaluation.

We are at your service right from the technical design phase, through the preparation of project documentation, technology delivery, actual implementation, test production to subsequent service and technical support.

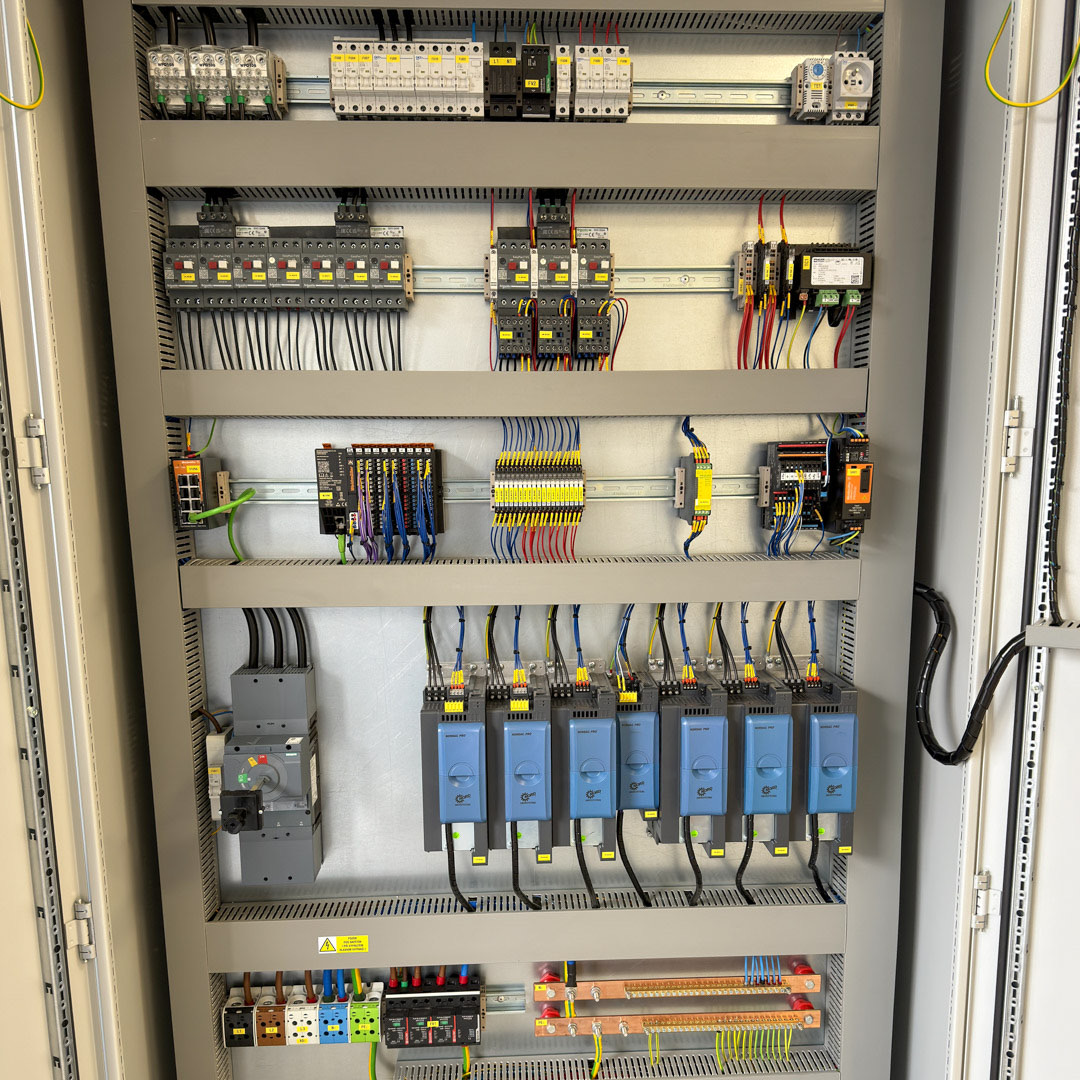

Design of electrical equipment

Design and manufacture of industrial switchboards (630A label), electrical installation (TIČR certificate), revisions. Power and MaR solutions for intelligent buildings. Projects and implementations for renewable sources small hydropower plants and FVE.

Technology

Design of entire process units in the food and machinery industry.

Dairies

Supplying technology, increasing efficiency and reducing energy demands

- Milk intake

- Raw milk storage

- Milk pasteurisation including cream skimming

- Cream pasteurisation

- Standardisation of milk and cream fat content

- Storage of pasteurised milk

- Storage of pasteurised cream

- Production of sour milk products, yogurt, specialities

- Pasteurisation of mixtures and specialities

- Production of butter

- Production of curd and curd cheese in makers and on tubs

- Whey manufacturing, centrifugation, thickening

- Reverse osmosis and ultrafiltration technology

- CIP stations of various capacities

01

COMPLEX DELIVERIES

From the very beginning, i.e. from the receiving and processing of raw milk to the production of final products and their distribution, we provide complete technological solutions.

With us, you will find everything you need for your production, which greatly simplifies the process and saves you time and resources.

02

MODERNISATION AND RECONSTRUCTION

We specialize in the modernization and reconstruction of existing equipment. Our innovations increase the efficiency of your production process and reduce energy demands.

This allows you to achieve cost savings without sacrificing product quality.

03

CUSTOMIZED

We work closely with our customers to develop and implement a computer control system that fully meets your individual needs.

With us, you will achieve excellent results and keep your competitive advantage. Together, we will transform your industry.

Contakt

Contact us for more information

APZ control systems s.r.o.

Sladovnická 145

583 01 Chotěboř

Czech Republic

IČ: 01769871

DIČ: CZ01769871

Slavomír Kadleček

+420 603 195 755

kadlecek@apzcontrolsystems.cz

Slavomír Kadleček ml.

+420 607 969 862

kadlecek.s@apzcontrolsystems.cz

Jan Lažínský

© APZ control systems s.r.o. | Webdesigned by Ladislav Prokop